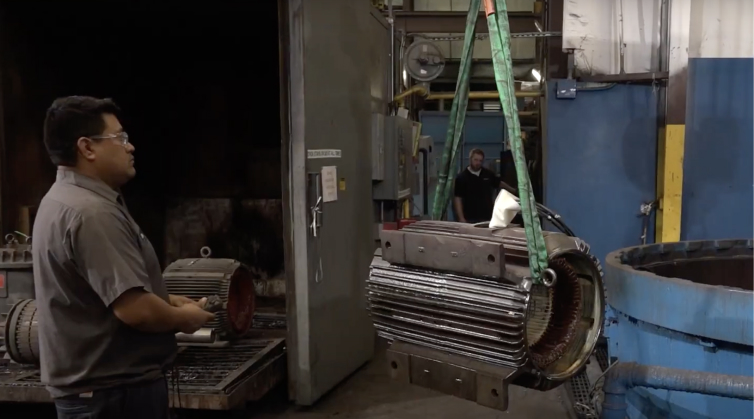

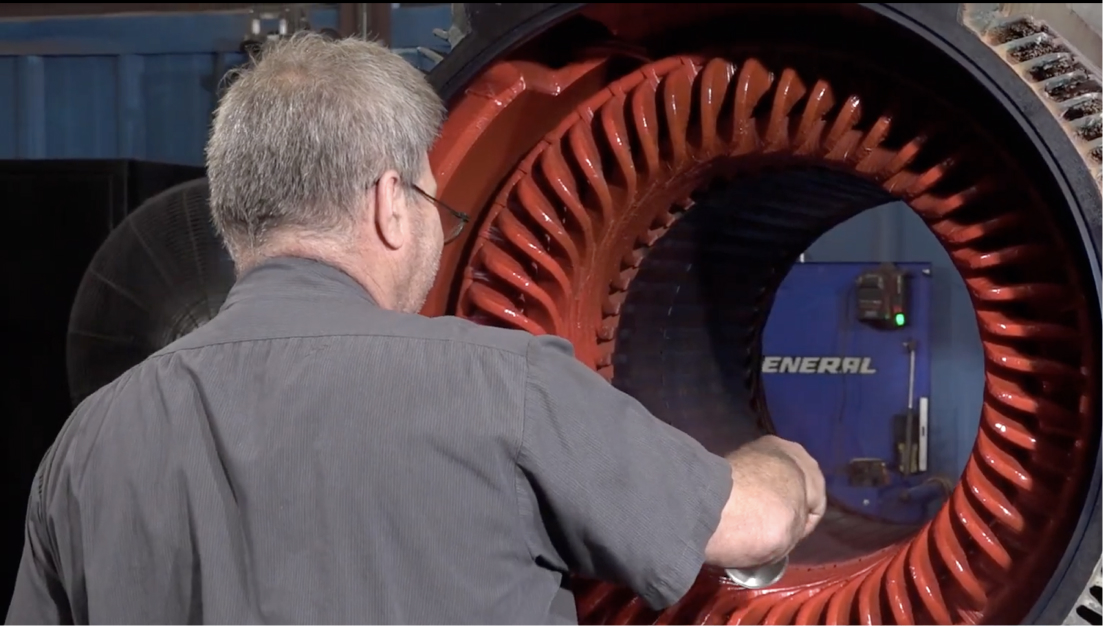

Electric Motor Shop features a state-of-the-art, clean-conditioned rewind facility designed to meet the needs of both high-voltage and low-voltage motor customers. Our advanced tools and experienced technicians ensure motors are rewound efficiently, safely, and with the highest quality standards. We have a state of the art 80x 80 clean- condition rewind and repair facility.

Expert Rewinds & Repairs

Electric Motor Shop features a state-of-the-art, clean-conditioned rewind facility designed to meet the needs of both high-voltage and low-voltage motor customers. Our advanced tools and experienced technicians ensure motors are rewound efficiently, safely, and with the highest quality standards. We have a state of the art 80x 80 clean- condition rewind and repair facility.

Baker Core-loss Machine

For evaluating magnetic core integrity

Baker AW12 Motor Diagnostic Equipment

Pinpoint diagnostic tool for motor health analysis

FLIR Camera

Thermal imaging to detect hot spots on stators and rotors

2 Large Temperature-Controlled Burn Out Ovens

Safely remove old insulation without damaging core integrity

2 Large Temperature-Controlled Bake Out Ovens

Ensures proper curing of new insulation materials

All Inverter Duty Magnet Wire

For durability in variable frequency drive applications

Class H Motor Insulation

High heat resistance for longer motor life

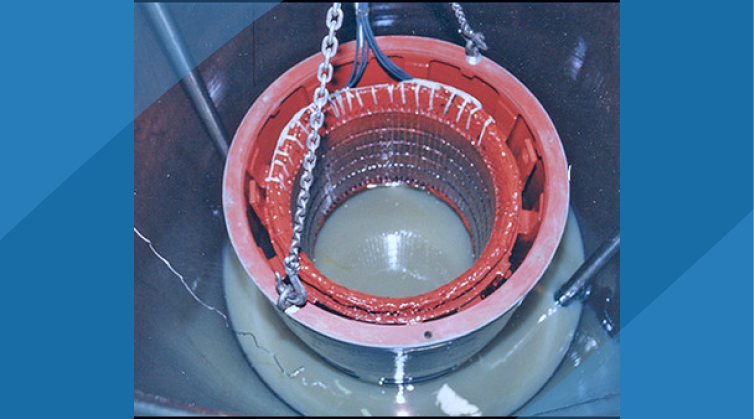

12 ft VPI Tank (Epoxy)

Vacuum Pressure Impregnation for deep, even resin penetration

10 ft Conventional Dip Tank (Water-Based)

Traditional insulation methods tailored to specific motor needs

AC Motor Rewinds

From 115 volts up to 13,200 volts

DC Motor Rewinds

Up to 750 volts

Facility Highlights

80ft x 80ft Rewind Faciltiy

Clean- Conditioned Rewind Facility

Six Highly Skilled Technicians

Fast turnaround times without sacrificing precision or quality

Samatic Rewind Machines

Ensuring accurate, constent winding

15-Ton Crane Capabilities

Expert safe handling of large and heavy equipment

Facility Highlights

80ft x 80ft Rewind Faciltiy

Clean- Conditioned Rewind Facility

Six Highly Skilled Technicians

Fast turnaround times without sacrificing precision or quality

Samatic Rewind Machines

Ensuring accurate, constent winding

15-Ton Crane Capabilities

Expert safe handling of large and heavy equipment

Baker Core-loss Machine

For evaluating magnetic core integrity

Baker AW12 Motor Diagnostic Equipment

Pinpoint diagnostic tool for motor health analysis

FLIR Camera

Thermal imaging to detect hot spots on stators and rotors

2 Large Temperature-Controlled Burn Out Ovens

Safely remove old insulation without damaging core integrity

2 Large Temperature-Controlled Bake Out Ovens

Ensures proper curing of new insulation materials

All Inverter Duty Magnet Wire

For durability in variable frequency drive applications

Class H Motor Insulation

High heat resistance for longer motor life

12 ft VPI Tank (Epoxy)

Vacuum Pressure Impregnation for deep, even resin penetration

10 ft Conventional Dip Tank (Water-Based)

Traditional insulation methods tailored to specific motor needs

AC Motor Rewinds

From 115 volts up to 13,200 volts

DC Motor Rewinds

Up to 750 volts

Contact Us

Main Office

Warehouse

For your convenience download then email or fax back the documents below.

Brochure

Contact Us

Main Office

Warehouse

For your convenience download then email or fax back the documents below.

Limited Warranty

Brochure